Star GB also are the sole United kingdom agent for FMB bar feeders and JBS tutorial bush systems, enabling us to supply one-source solutions for mill-convert purposes backed by unrivalled client support.

CNC lathes from WEILER promise precision and effectiveness within the machining of workpieces from numerous types of products – for a lot more than forty years.

The Tsugami SS38MH-5AX sliding headstock lathe with B-axis is often a chucker-convertible, high-performance automatic CNC lathe which offers total 5-axis simultaneous machining with a FANUC 31i-B5 Manage. This machine’s backworking overlap with Are living tool capability allows for numerous tools while in the Lower and is also equip with a total of 52 tools, which include a forty tool magazine, 10 tools within the back again tool put up, and an optional 2 tools on the deep hole drill holder. 5 modular kind live tools on again tool submit for ideal allocation of machining capacity.

Vertical Turning Lathes Vertical lathes have long been recognised for their positive aspects inside the machining of weighty or quick workpieces.

During the realm of precision machining, each and every detail counts. Allow us to assist you be certain that your work not just satisfies but exceeds expectations.

By comprehending the variances between fastened and sliding headstocks, manufacturers might make knowledgeable choices when choosing a CNC lathe machine that aligns with their distinct machining plans and manufacturing prerequisites.

Market Apps: Perfect for demanding sectors that need exceptionally restricted tolerances and dependability over long durations.

The CNC lathe machine headstock is an important and integral Section of the overall machine construction. Positioned with Read more the remaining finish of your lathe bed, it serves as the central hub for that rotational motion of your workpiece during machining functions.

They function by spinning the workpiece and cutting it with tools, all controlled by exact computer programming. This allows them to provide parts quickly, properly, and constantly.

In manufacturing, The search for precision is never-ending. As we delve into the most beneficial high precision CNC lathes for 2024, keep in mind that these machines are at the forefront of technological know-how, pushing the boundaries of what’s possible when it comes to accuracy, performance, and trustworthiness.

The spindle, mounted within the headstock, is the primary rotating ingredient that holds the workpiece set up through machining. Spindles are intended with precision taper roller bearings and ball bearings for easy and secure rotation.

This innovation may be the primary reason why swiss lathes are so exact. The workpiece moves out to satisfy the tool, which implies which the lateral force professional through the component is noticeably smaller as a result of reduced second arm. This, in turn, allows for highly precise machining.

The headstock also has the bearings that guidance the spindle. High-precision bearings lower vibrations and increase rotational accuracy, that's critical for developing high-high-quality parts.

CNC sliding headstock machines from TRAUB are made for specific and successful producing of long and slender parts with a highest diameter of 32 mm.

Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Joshua Jackson Then & Now!

Joshua Jackson Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Soleil Moon Frye Then & Now!

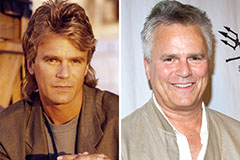

Soleil Moon Frye Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!